Full speed ahead with tilapia fry throughout Vietnam

Selection for fast-growing broodstock is leading development and fry production in Vietnam.

Broodstock and fry production

In 2016, Sheng Long Bio-Tech International, a leading aquafeed producer in Vietnam, was quick to respond to the expected demand for quality fry and fingerlings. It began to import broodstock genetically selected for fast growth and high fillet yield from China. In 2018, it expanded its hatchery in Soc Trang to supply 200 million fingerlings/year of both black and red tilapia.

All of this happens in the 8.5ha hatchery and breeding centre in Soc Trang, located within the 18ha Sheng Long research centre. Here, it is selective breeding for fast growth and colour with red tilapia founder broodstocks originally from China. “We have entered the tilapia fry market with a capacity of 100 million fry per year. In Vietnam, the red tilapia is grown in cages in tributaries in the Mekong Delta, whereas the black tilapia, in ponds,” said Chew Uik Sen, Technical Manager, adding that in 2023, it received a license to build a new hatchery to double capacity by 2024.

“We have been doing breeding of the red tilapia over 2-3 years here in Vietnam. The main breeding trait is the fast growth of the red tilapia Oreochromis sp. In the case of the black tilapia Oreochromis niloticus, selectively bred broodstocks are imported from the Genetically Improved Farmed Tilapia (GIFT) breeding facility in China and used directly for fry production. We started to establish Sheng Long broodstocks here in Vietnam,” said Chew. “We have been working to bring down the colouration. In China, the red tilapia is very red, while in Vietnam, the preference is pink to almost white.”

Fry production

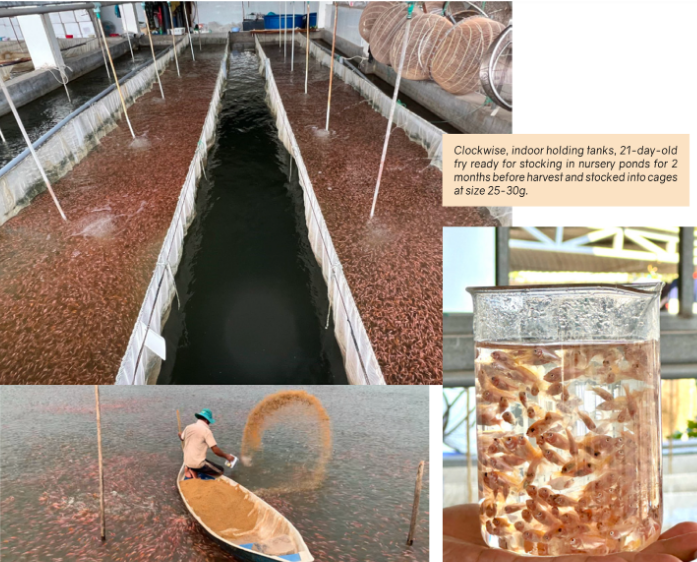

Breeding is carried out on a weekly basis, via natural spawning. In 24 hours, eggs are collected from broodstock. The larvae and fry rearing process are in three

stages. The first stage is from day 1 of post hatching to day 7. Here, the survival rate is 80 to 85%. The next stage is days 8-14 when the digestive system begins to develop, and the survival rate reaches 95.5 to 97.5%. In the third phase, from day 15 to day 21, the fry is nursed until fully developed with a survival rate of 98-99.9%.

“The process is in outdoor ponds and we change the nets every seven days. We sell 21-day-old fry. Throughout this 21-day process and prior to distribution to the farmers, the team will examine fry under the microscope for pathogens and parasites. Our promise is to deliver streptococcus-free fry to farmers as well as uniform specification.”

In the case of red tilapia, the hatchery sells size 3000/kg (0.3g) fry and farmers grow-out 25-30g fingerlings in nursery ponds for two months. These fingerlings are transported by boat to the customers’ cages for further grow-out. On average, the farmer will stock 70-85 fry/m2 in the nursery ponds. The survival rate in the nursery stage is 70 to 90%.

A team of technicians regularly visits customer fish farms and reports back on the performance of fish fry. They will also collect data on growth performance in grow-out stages, in ponds and cages. “Our red tilapia grows fast. In four to five months, they reach 700g. This is the base size and the largest, 1.5kg. The fingerlings produced by other hatcheries grow slower, at about one month behind,” said Chew.

Sheng Long bundles fry and fish feed. “We believe that for high growth performance, the fish should be fed with our feed formulated for the best performance. The crude protein ranges from 34% for the early stages to 28% for the grow-out phase. Feed conversion ratios (FCR) reported by our farmers are 0.82 to 1.03 for grow-out of size 0.25-0.3g to 25-30g harvests in ponds, and 1.56 to 1.65 for grow-out of size 25-30g to 700g-800g harvests in cage culture in rivers.”

Fry market

Sheng Long distributes its annual production to farms across the entire Vietnam market. The leading markets are An Giang in the Mekong Delta and Nam Dinh in the north. Currently, there is one hatchery in Soc Trang in southern Vietnam.

Costs of production

“It is critical that our farmers have the best performance tilapia to make the best profit,” said Chew. “We estimate their cost of production at VND24,000/kg (USD0.93/kg) for size 700g harvest.”

In terms of production costs, feed costs VND18,800/ kg in 2023. The cost of red tilapia fry is VND300/fry (USD11.73/1000 fry) and for black tilapia, it is VND500/fry (USD19.56/1000 fry). Currently, the farmgate prices for the red tilapia are up to VND33,400/kg (USD1.30), while it is around VND27,000/kg (USD1.05) for the black tilapia.”

Marketing and buyback tilapia

The red tilapia is sold as chilled fish in local markets, while black tilapia is exported as whole frozen or frozen fillets. Since 2018, Sheng Long has been involved in a small way fish processing at its processing plant in Ca Mau. It buys

back tilapia and other freshwater fish from its farmers and the open market. However, when the contract price is lower than the current farmgate price, the farmer will sell to buyers who, in turn, will sell in the fish market. The export markets for its frozen tilapia, round whole and fillet are Europe, Japan and Malaysia.

“We only process black tilapia, while a few other factories export frozen red tilapia. Our preference is 1.2kg black tilapia, but with poor uniformity in sizes, we are limited by the, in sizes available, which range from 700g to 1.2kg. Therefore, smaller fish of 500g to 800g are sold as chilled fish in the local market. We process over 800g tilapia as whole frozen. For larger fish of 2kg, we can get 40% yield as skinless fillet,” said Anny Chau Bac Anh, GM Assistant.

The Ministry of Agriculture and Rural Development (MARD) had pushed for a production of 400,000 tonnes of tilapia by 2030. Tilapia would be the second freshwater fish for export, reducing the reliance on pangasius exports. It will be small compared to the leading role of the pangasius, currently with an annual production of 800,000 tonnes.

Aquaculture Asia Pacific

July/August 2024