The inclusion effects of the corn protein concentrate (Empyreal 75) in replacing fishmeal to optimize the commercial production of Asian seabass fish (Lates calcarifer)

Nguyen Duy Hoa, PhD. -Technical Director for Empyreal products, Cargill Inc.

Asian seabass (Barramundi) and other carnivorous fish species such as golden pompano, salmon, and sturgeon, etc. require high protein level and low carbohydrate (especially starch), and low ash content in their diets. Empyreal 75 (CPC), a highly pure and concentrated corn protein product from Cargill Inc., is well-suited for these species due to its high protein content (minimum 75%), low carbohydrate (5.3%), very low starch (max 1%), and low ash (1.3%). Empyreal 75 also contains high levels of amino acids—especially methionine (1.7%), glutamic acid (15.29%), leucine (12.63%), proline (6.68%)—and is rich in health-promoting nutrients (carotenoids, vitamin A, polyphenols, phytosterols, inositol, Omega-6: linoleic acid). In addition, it contains no anti-nutritional factors, making it an excellent sustainable alternative to fishmeal in aquafeeds. This article presents the results of replacing fishmeal with Empyreal 75 in Asian seabass feed across three stages: fry, nursery, and grow-out. The goal was to determine the optimal inclusion level of Empyreal 75 when replacing fishmeal in Asian seabass’s feed to provide the base for commercial feed production during nursery and grow-out cage farming.

Research methodology

Fry Stage Experiment

This experiment is to determine the optimum inclusion in replacing fishmeal in Asian seabass’s feed. Five feed formulated diets were designed with similar protein (44%) and fat (12%) levels. The control diet contained 36% fishmeal, while the test diets replaced fishmeal with Empyreal 75 at 5% (5%CPC), 7.5% (7.5% CPC), 10% (10%CPC), and 12.5% (12.5% CPC) inclusion levels (Table 1). Fry averaging 1.34 ± 0.04 g were randomly distributed into 20 tanks (4 tanks as 4 replicates per diet) and cultured under a continuous flow-through water regime (500% water exchange/day) for 62 days.

The optimal inclusion level of CPC determined from this trial was then applied to replace fishmeal in commercial feeds for the feed mill in both nursery and grow-out stages to evaluate fish performance during commercial nursery and grow-out cages.

Nursery Stage Experiment

Two diets with similar protein (48%) and fat (10%) were tested, including commercial feed containing 3% Empyreal 75 from a feed mill served as the control and a test diet with 10% CPC (an additional 7% CPC replacing fishmeal in the control diet). 4 cement tanks (275 x 275 x 1000 cm) acts as 4 replicates per dietary treatment with 1250 fish averaging 2.73 ± 0.27 g per tank under the same flow-through water regime 500% water exchange/day) for a period of 40 days.

Grow-out Stage Experiment

Two diets with similar protein (44%) and fat (10%) were tested, including commercial feed containing 3% Empyreal 75 from a feed mill served as the control and a test diet with 10% CPC (an additional 7% CPC replacing fishmeal in the control diet). Fish from the nursery trial were size graded, respectively for dietary treatment and stocked into 3 cages (3.0 x 3.0 x 3.0 m) as 3 replicates per diet, with 750 fish per cage. Initial weights were 37.78 ± 0.29g for the control treatment and 39.01 ± 0.28g for the 10%CPC treatment, and the trial lasted 120 days.

Water quality, Biomass, final body weight (FBW), feed conversion ratio (FCR), thermal growth coefficient (TGC), percent weight gain (PWG), and survival rate (SR) were evaluated. The Fry Stage Experiment was carried out at Gondol-Bali Research Center, Indonesia and The Nursery and Grow-out stages was carried out at PT Bali Barramundi Commercial Farm, district of Patas, Gerokgak – Indonesia.

Table 1. Five dietary treatments for Fry Stage Experiment

| Diet name | Control | 5% CPC | 7,5% CPC | 10% CPC | 12,5% CPC |

| Menhaden fishmeal | 36.00 | 29.86 | 26.80 | 23.74 | 20.67 |

| Poultry meal | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 |

| Soybean meal | 20.00 | 20.00 | 20.00 | 20.00 | 20.00 |

| Empyreal 75 (CPC) | 0.00 | 5.00 | 7.50 | 10.00 | 12.50 |

| Aker Bio Krill meal | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Menhaden fish oil | 4.00 | 4.55 | 4.83 | 5.10 | 5.40 |

| Soy oil1 | 3.50 | 3.50 | 3.50 | 3.50 | 3.50 |

| Corn Starch1 | 0.17 | 0.41 | 0.51 | 0.63 | 0.72 |

| Whole wheat4 | 17.00 | 17.00 | 17.00 | 17.00 | 17.00 |

| Marine fish mineral premix | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| Marine fish vitamin premix | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Choline chloride | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

| Rovimix Stay-C 35% | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

| CaP-dibasic | 1.50 | 1.50 | 1.50 | 1.50 | 1.50 |

| L-Arginine | 0.00 | 0.11 | 0.17 | 0.22 | 0.28 |

| L-Lysine | 0.00 | 0.24 | 0.36 | 0.48 | 0.60 |

| Methionine Microcaps | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

| Taurine | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Vitamin E | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| Formulation cost ($/kg) | 1.452 | 1.414 | 1.395 | 1.376 | 1.357 |

Results & Discussion

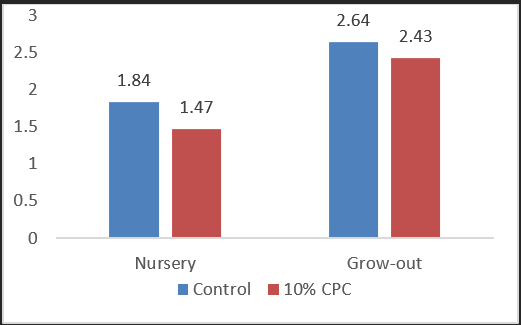

Results from the Fry Stage Experiment (Table 2) Indicates fish performances from 5% CPC, 7.5% CPC, 10% CPC và 12.5% CPC with significantly higher biomass, higher final body weight and higher percentage of weight gain (P< 0.05) vs those of the fish performances from the Control and the optimum inclusion is 10% CPC. Feed conversion rate (FCR) is not significant difference (P> 0.05) when comparing the Control with the 5% CPC & 7.5% CPC while it is significantly lower for the 10% CPC & 12.5% CPC vs the Control (P< 0.05). In addition, feed cost per kg of fish weight gain recorded the lowest for the 10% CPC vs the control as well as the other CPC treatments (Figure 1).

Figure 1. Feed cost per kg of fish weight gain ($/kg)

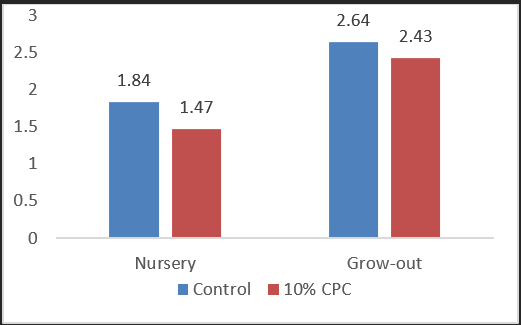

Figure 2. Feed cost per kg of fish weight gain ($/kg)

Results from both Nursery and Grow-out stages shows that when replacing fishmeal in the control commercial diet, the 10% CPC feeds support significantly higher final body weight and lower feed conversion rates, and higher survival rates (Table 3 & 4).

Economic Efficiency of the Empyreal 75 with the optimum 10% CPC inclusion is also proven with lower feed cost per kg of fish weight gain vs the control feed in all fry, nursery and grow-out stages (Figure 1& 2).

Table 2. Results of the 5 treatments from Fry Stage Experiment

| Treatment | Biomass | FBW | FCR | TGC | PWG | SR |

| Control | 9352.83d | 52.85d | 0.91a | 0.1397d | 3883.99d | 88.63 |

| 5% CPC | 11118.11c | 62.22c | 0.85ab | 0.1505c | 4494.91c | 89.25 |

| 7.5% CPC | 12925.98b | 70.06b | 0.80abc | 0.1593b | 5170.45b | 92.25 |

| 10% CPC | 14695.27a | 78.18a | 0.65c | 0.1670a | 5656.29a | 94.00 |

| 12.5% CPC | 11887.40bc | 66.09bc | 0.72bc | 0.1551bc | 4865.08bc | 90.00 |

| P-value | <0.0001 | <0.0001 | 0.0319 | <0.0001 | <0.0001 | 0.7631 |

| PSE6 | 489.53627 | 1.5882 | 0.0556 | 0.0019 | 153.1822 | 3.3019 |

Table 3. Results from the Nursery Stage Experiment

| Treatment | Biomass | FBW | FCR | TGC | PWG | SR (%) |

| Control | 42784.23b |

30.76b |

1.27a |

0.1423a |

1052.14a |

92.72b |

| 10%CPC | 52429.97a | 36.48a | 1.03b | 0.1565b | 1232.79b | 95.82a |

| P-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| PSE6 | 692.4133 | 2.2464 | 0.0787 | 0.0027 | 216.6651 | 4.6704 |

Note: Biomass (g) FBW = Final body weight (g); FCR = Feed conversion ratio; TGC = Thermal growth coefficient; PWG= Percentage weight gain; SR = survival rate; and PSE = Pooled standard error.

Table 4. Results from Grow-out Stage Experiment in Cages

| NT | Biomass | FBW | FCR | TGC | PWG | SR |

| Control | 251.41a | 372.55b | 1.82a | 0.1046a | 886.03 | 89.98b |

| 10%CPC | 271.16a | 388.00a | 1.69b | 0.1063b | 894.75 | 93.19a |

| P-value | <0.0001 | 0.0017 | <0.0001 | 0.0207 | 0.4264 | 0.0076 |

| PSE7 | 12.1656 | 2.5267 | 0.0085 | 0.0005 | 12.0629 | 0.7891 |

Note: Biomass (kg); FBW = Final body weight (g); FCR = Feed conversion ratio; TGC = Thermal growth coefficient; PWG= Percentage weight gain; SR = survival rate; and PSE = Pooled standard error.

Conclusion & Recommendation

Empyreal 75 is an excellent protein source to replace fishmeal. A 10% inclusion level yields superior results in weight gain, biomass, survival rate, and feed efficiency, while also reducing feed cost per kg of fish produced. Therefore, Empyreal 75 offers a sustainable and economically viable solution for Asian seabass fish and other aquaculture marine fish as well.